PP filter element (meltblown, folded)

Category:

E-mail:

Product Description

Microporous folded membrane filter element

Polypropylene folded filter element

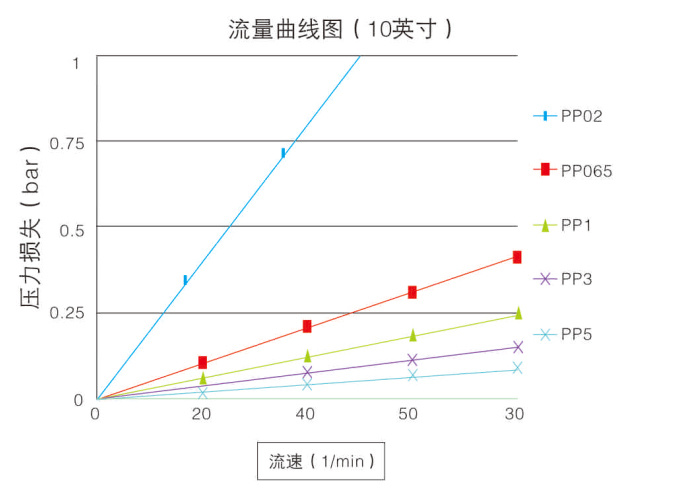

Main technical parameters

|

Precision (μm)

|

0.2 0.45 0.65 0.8 1 2 3 5 1020 25 30 50 75 100

|

||

|

Length

|

5"10”20"30"40"

|

Working temperature

|

<60℃

|

|

Diameter

|

2.75"

|

Maximum temperature resistance

|

<90℃

|

|

Filtering materials

|

PP (Polypropylene)

|

Max inlet pressure

|

5.1bar ( 25℃ )

|

|

Support materials

|

PP (Polypropylene)

|

2.4bar ( 60℃ )

|

|

|

Materials of case

|

PP (Polypropylene)

|

Recommended changeover pressure difference

|

1bar

|

|

Filtering area

|

0.5 square meters / 10"

|

Max pressure difference

|

3.2bar ( 25℃ )

|

Polypropylene melt-blown filter element

Features:

Made of polypropylene, produced using melt-blown technology, continuous polypropylene long fiber winding to form tubular filter material

High filtration accuracy, large flow, uniform structure, large dirt holding capacity, long service life

Good chemical compatibility, no additives, fibers are not easy to fall off

Widely used, high dirt retention capacity

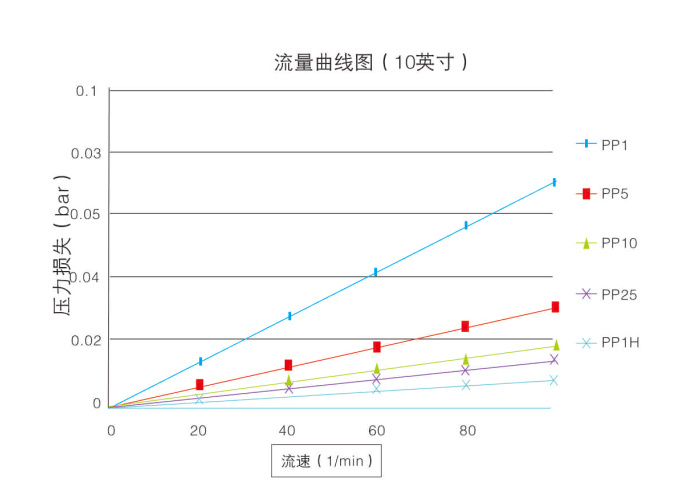

|

Precision (μm)

|

0.5 1 3 5 10 20 25 30 50 75 100

|

||

|

Length

|

5”10"20"30"40"

|

Working temperature

|

<60℃

|

|

Diameter

|

65mm

|

Max temperature resistance

|

<90℃

|

|

Filtering materials

|

PP (Polypropylene)

|

Max inlet pressure

|

5.2bar ( 25℃)

|

|

Internal/external support

|

PP (optional) (Polypropylene, optional addition)

|

2.6bar ( 60℃ )

|

|

|

Interface

|

PP (optional) (Polypropylene, optional addition)

|

Recommended changeover pressure difference

|

1bar

|

|

Interface

|

0.05 square meters / 10"

|

Max pressure difference

|

3.5bar ( 25℃ )

|

Metal folded filter element

Stainless steel folded filter element made of sintered stainless steel fiber felt and composite thick stainless steel wire mesh, folded and rolled to form a multi-layer filter element, usually divided into three layers and five layers. Sintered stainless steel fiber felt is a porous depth filter material made from stainless steel fibers sintered at high temperatures, with a gradient pore size from coarse to fine.

Features:

High porosity, strong breathability, low resistance, low operating pressure difference

High strength, can withstand high pressure and high pressure difference

High temperature resistance (≤300℃), corrosion resistance, suitable for filtering high viscosity media

Excellent regenerability, can be reused multiple times after chemical cleaning, high temperature and ultrasonic cleaning

After being folded into a corrugated shape, the filtering area is large, and the dirt holding capacity is strong

Main technical parameters

Stainless steel precision filter element maximum working temperature: ≤500°C filtering accuracy: 3-200μm.

Maximum working pressure: 25MPa; maximum working pressure difference: 8Mpa filter element specifications: can be made according to user requirements.

Key words:

PP filter element (meltblown, folded)

Related Products

Scope of application: PP,PA,PE slice spinning sheet, PP spunbond non-woven fabric, with protective spinning mercury; Plastic (PVC, PBT, PA, PP, PE, PS) granulation production line.

PP filter element (melt blown, folded)

Scope of application: PP,PA,PE slice spinning sheet, PP spunbond non-woven fabric, with protective spinning mercury; Plastic (PVC, PBT, PA, PP, PE, PS) granulation production line.

Scope of application: PP,PA,PE slice spinning sheet, PP spunbond non-woven fabric, with protective spinning mercury; Plastic (PVC, PBT, PA, PP, PE, PS) granulation production line.

Scope of application: PP,PA,PE slice spinning sheet, PP spunbond non-woven fabric, with protective spinning mercury; Plastic (PVC, PBT, PA, PP, PE, PS) granulation production line.

Welcome your message consultation

Any questions? Keep in touch. We 'd love to hear from you.